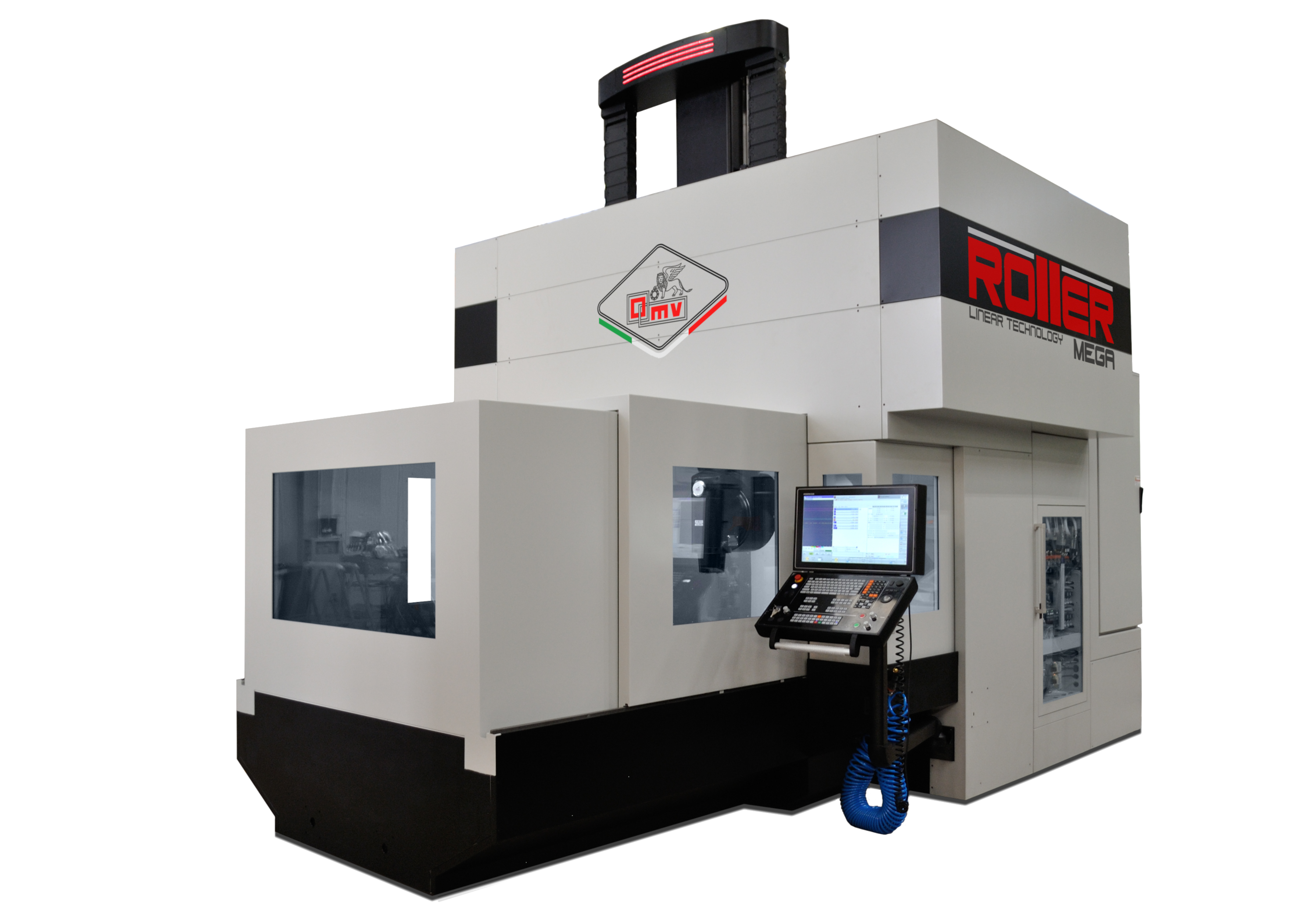

Fixed portal and moving table

ROLLER MEGA

OMV adds to its product range a new high-speed portal machining center model ROLLER MEGA

Applications

The axes movements are all controlled by linear motors. The slides are all on integral linear roller guides in the three axes that reach a feed speed of 60000 mm/1′. The head, with a continuous axis of work and a positioning axis (two continuous axes of optional work), is driven by torque motor and is equipped with an electrospindle at 18000 g/ 1′ with power of 29 Kw. tilting in the transverse axis of 110 μ. The longitudinal and transverse motion guides are protected by heat-sealed bellows and telescopic steel guards. The machine is equipped with a tool magazine without an exchange arm with 42 or 84 seats, positioned outside the working range. The chips are evacuated by augers that transport them in a conveyor of dredging chips with side exit. The fairing with tunnel opening solution that leaves the load table completely free

Longitudinal axis

2.050 mm 80.71 In

Cross axis

2.050 mm 80.71 In

Vertical axis

1.100 mm 43.31 In

Feeds

0 ÷ 60.000 mm/1` 0 ÷ 2362.20 In/1`

Spindle

37 Kw • 18.000 ÷ 22.000 rpm

Spindle taper

HSK-63A • HSK-100A

Multitasking

Available heads

Torque up to Nm

190

Power up to Kw

47

Speed up to rpm

18.000

Spindle taper

HSK-63A / HSK-100A

Bi-rotative head with motorspindle

Torque up to Nm

190

Power up to Kw

47

Speed up to rpm

18.000

Spindle taper

HSK-63A / HSK-100A

Fork head with motorspindle

Torque up to Nm

280

Power up to Kw

63

Speed up to rpm

10.000

Spindle taper

ISO50 / HSK-100A

Universal head with continuous positioning and motorspindle